Beginnings

So I have had for many years a stormtrooper helment.

So I have had for many years a stormtrooper helment.

I’ve always wanted a whole stormtrooper but (quality) suits are stupidly expensive. So I’ve started doing something equally stupid.

I’m building one.

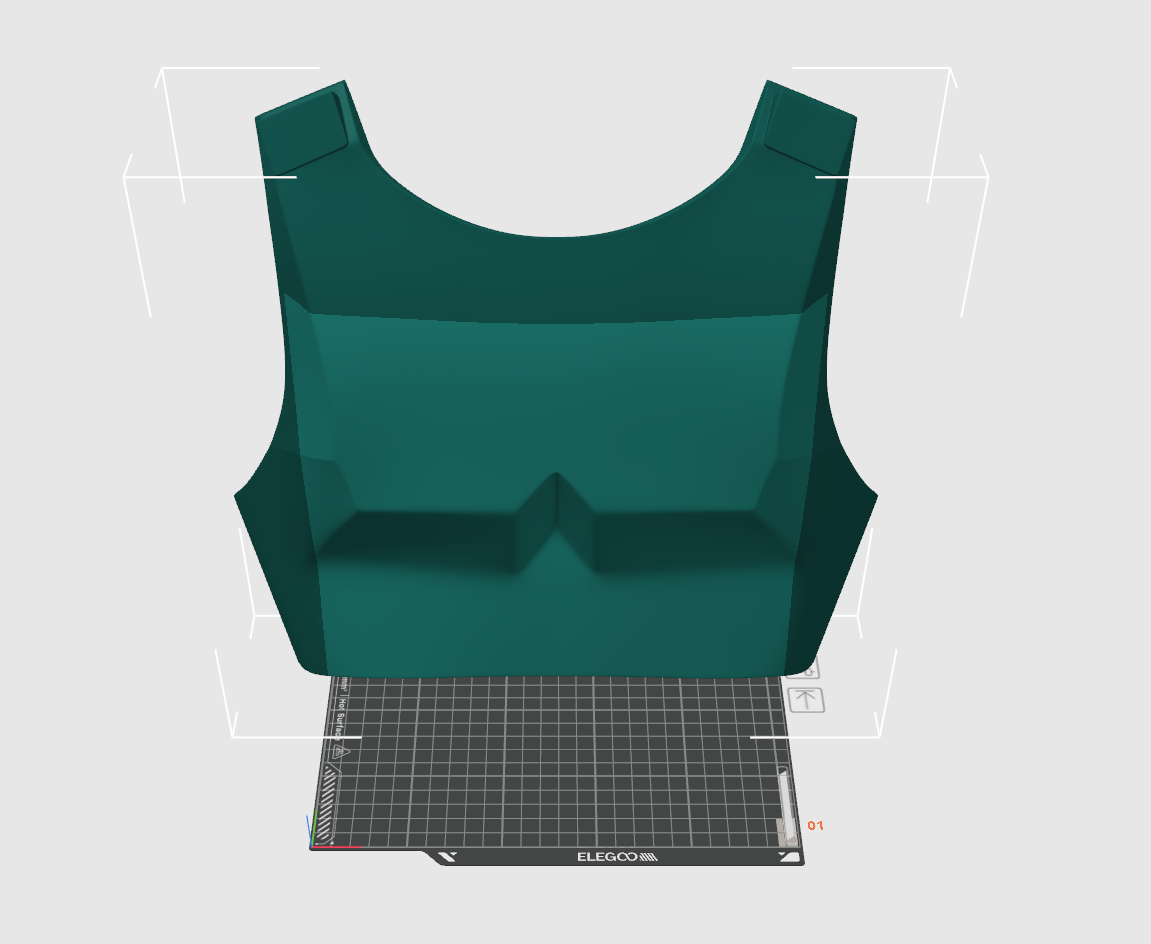

Starting with the chest piece, which took several prints to get right, I’ve been learning how to tune my printer and how to properly slice models for printing.

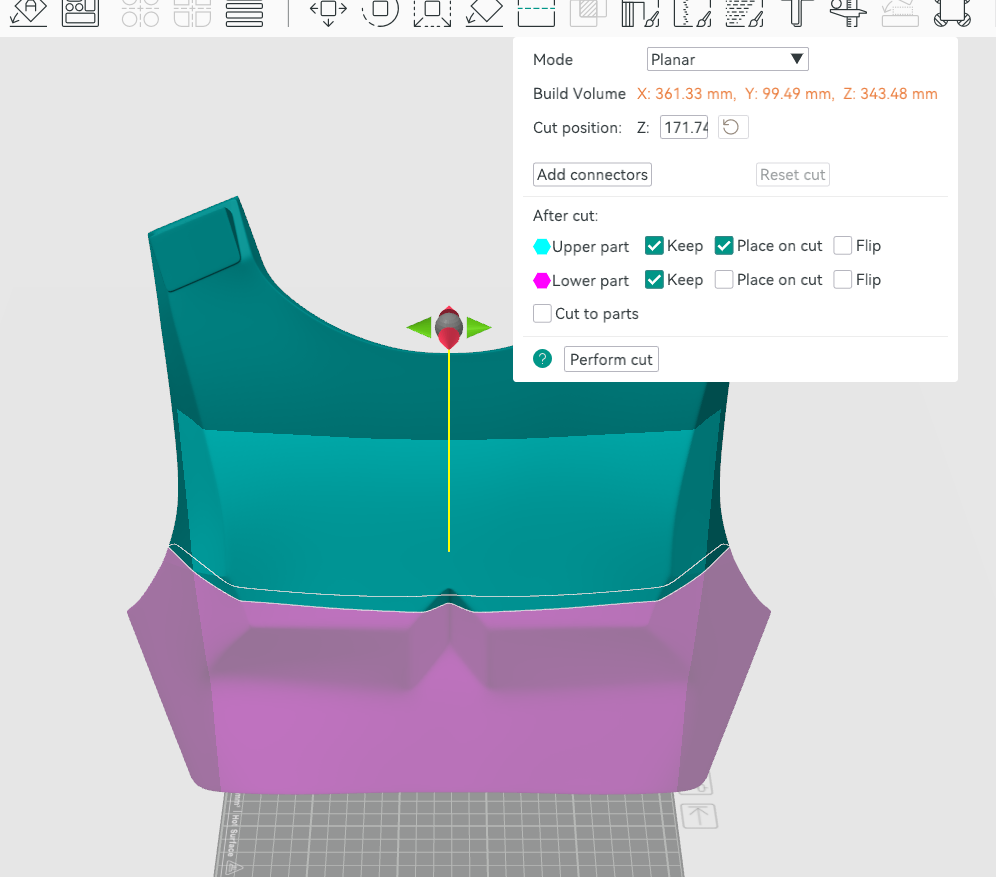

Probably one of the most difficult aspects is how to handle parts that are far too large for my 256mm^3 print volume. Well, you have to cut it up, print it, then assemble the parts. I failed at this a couple of times before learning how to configure ‘connectors’ in OrcaSlicer.

Clearly, not gonna fit. Orcaslicer has a ‘cut’ feature allowing you to split a model on any angle however, aligning these after printing to glue together is …. difficult.

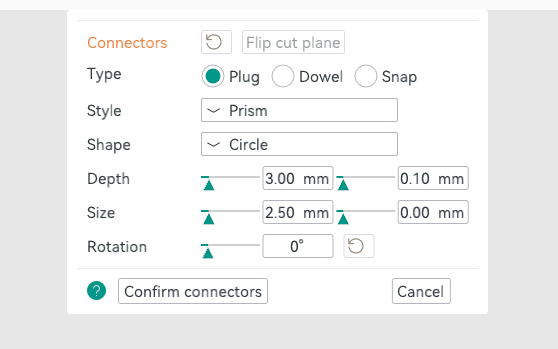

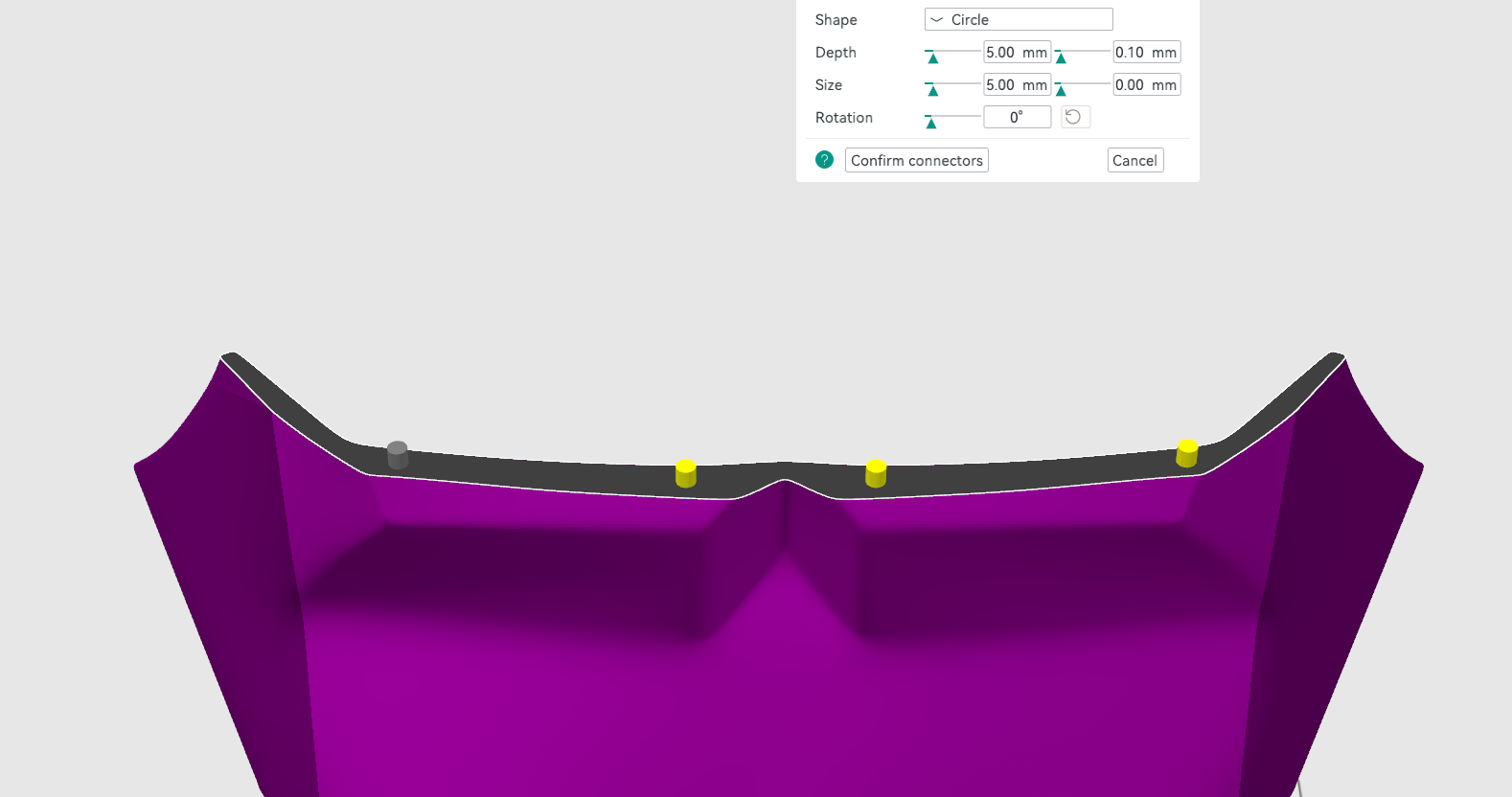

Enter: Connectors!

After much experimentation, 5mm x 5mm has been working well for me. Smaller, and you risk snapping them off trying to assemble the parts.

Once you’ve configured the connectors, click on the places on your model where you want connectors added.

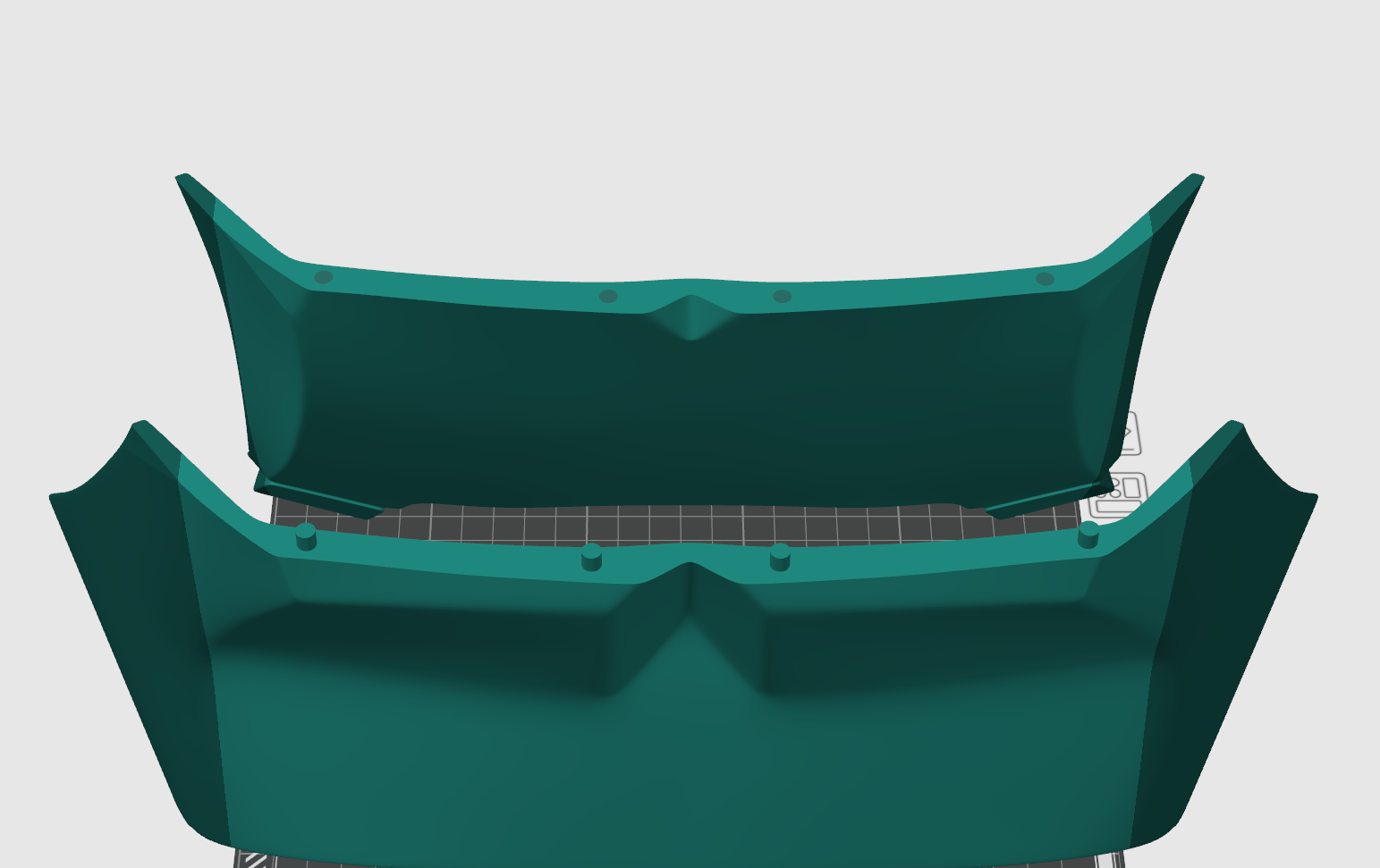

When you’re happy with the placement, make the cut. Then you can cut further, or arrange the parts for printing.

That’s it. Well, then you have to arrange them on the print bed, configure supports if needed, print, hope for the best.